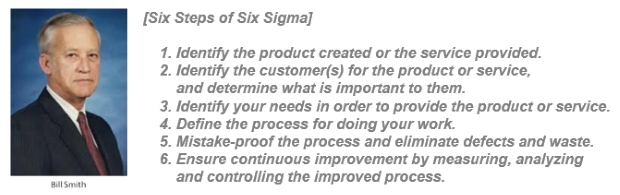

1986년 모토롤라에서 시작된 Six Sigma 활동은

처음에는 식스시그마 개념을 만든 모토롤라의 부사장 빌 스미스(Bill Smith)가 정의한

1990~1993년 마이클 해리(Mikel Harry)가

1996년 GE에서 전사적인 문제해결방법으로 Six Sigma를 도입하였을 때...

1988년 미국의 국가 품질상인 제1회 말콤볼드리지상을 수상하면서 다른 업체로 전파되기 시작하였다

모토롤라의 식스시그마 활동을 전파하기 위해 하나의 정립된 Process가 필요했는데,

1988년 3월에 발족한 모토롤라 사내대학의

DFM(Design for Manufacturing) Training Program에서 부터 시작되었다

“Six Steps of Six Sigma”으로 시작되었다

1. Identify the product created or the service provided.

2. Identify the customer(s) for the product or service, and determine what is important to them

(requirements in measurable terms).

3. Identify your needs in order to provide the product or service.

4. Define the process for doing your work.

5. Mistake-proof the process and eliminate defects and waste.

6. Ensure continuous improvement by measuring, analyzing and controlling the improved process.

위의 여섯단계 Process에는 우리가 아는 DMAIC(처음에는 MAIC였음)의

핵심이 모두 들어가 있지만 DMAIC라기 보다는

Juran Cycle이라고 불리는 PDCA Cycle에 더 가까운 Process 였다.

모토롤라 사내대학의 "Six Sigma Institute"의 연구 활동중에 위의 여섯단계의 Process를

Machine과 Process의 Problem Solving Process로 재해석하여

MAIC(Measure-Analyze-Improve-Control)의 4단계 Process로 만들었다

MAIC 4단계 Process에는 개선을 왜 해야 하는가에 대한

적절한 정의를 내리는 부분이 불명확하다고 판단하여

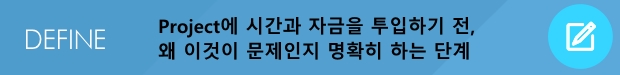

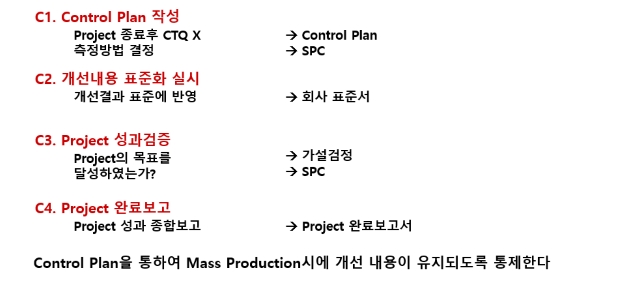

1997년 MAIC Process 앞단계에 문제의 정의단계인 'Define'을 추가한

DMAIC(Define-Measure-Analyze-Improve-Control)의

5단계 Process로 진화하여 오늘에 이르고 있다.